2014 – 2016

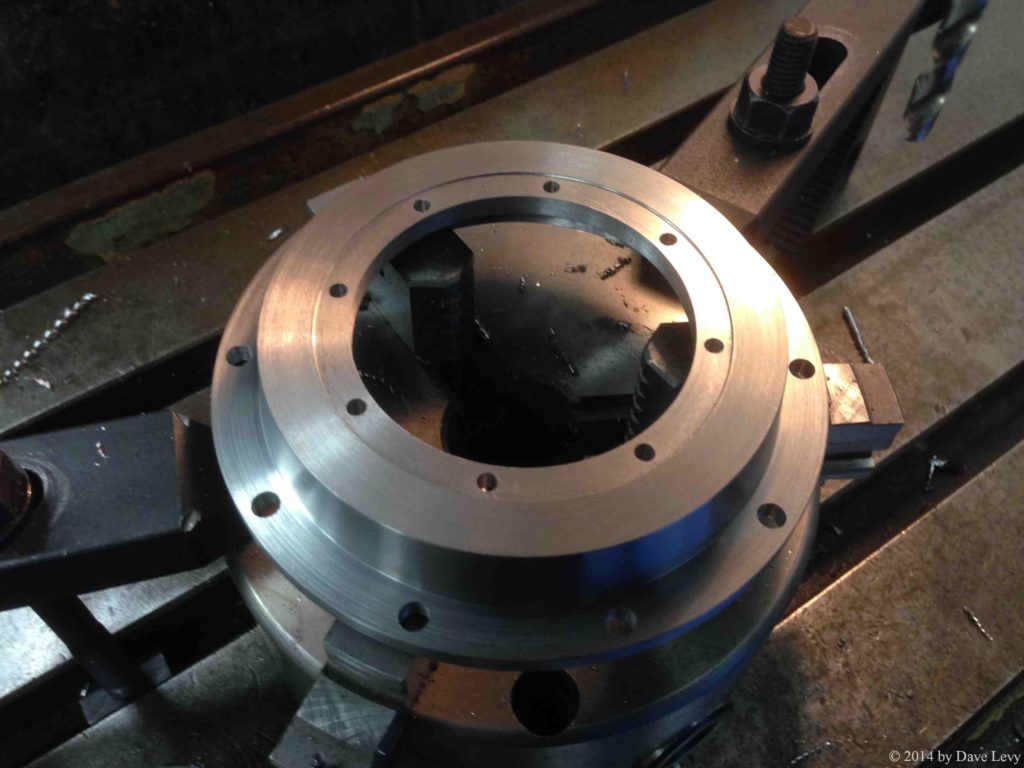

Ring Gear and Spacer (01/19/2014)

I’ve been trying to spend some time working on this project again. I finally got the material I needed for turning the ring gear spacers. First I machined all the bevel gears. The ring gear took the most work (see pictures of finished gears below). Once I had them ready then I set about machining the spacers from 1″ thick discs of 12L14 with a 5″ diameter. Since I don’t really have any accurate plans, it took a bit of trial-and-error to find the thickness that was needed. Now I just have to make 5 more of them.

Working Gears!! (03/16/2014)

The spacers are done and assembled. It works!! To watch it run, click here. Now I just have to do the other two trucks..

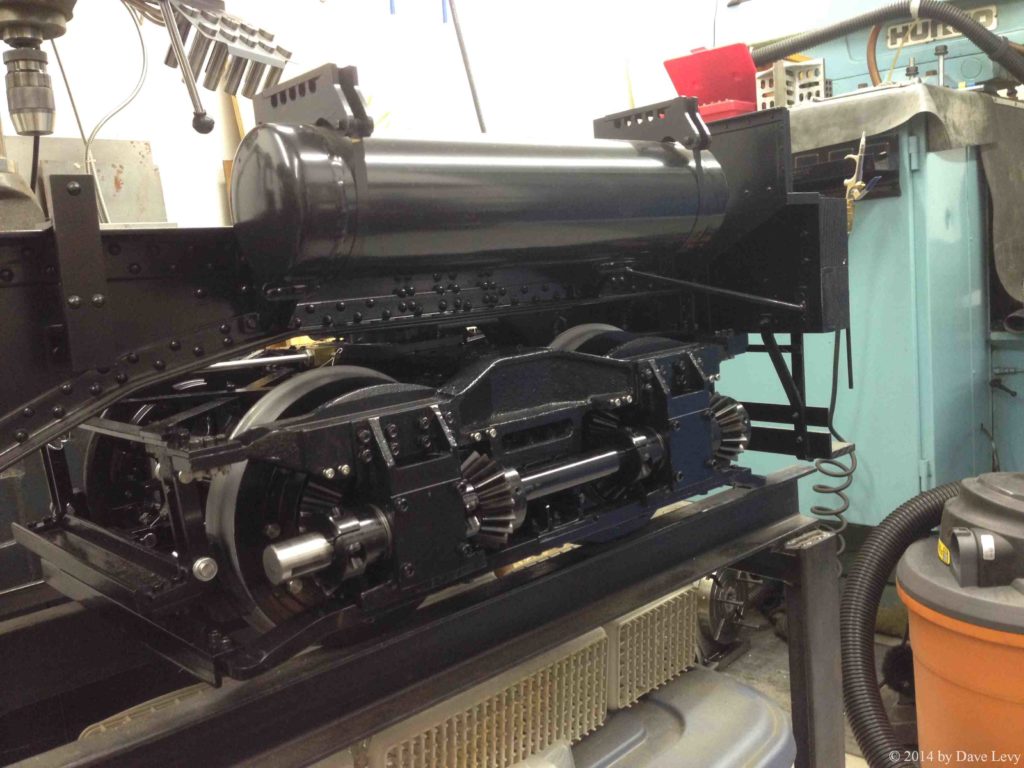

One (Front) Truck Completed (7/23/2014)

Well I finally have one truck assembled, painted, and under the frame. It actually works to boot!! The other two should go faster since I made most of the fiddly little parts and bits for them as I did the first truck. Maybe in a couple of months I will have all three of them done.

Second (Center) Truck Completed (12/6/2014)

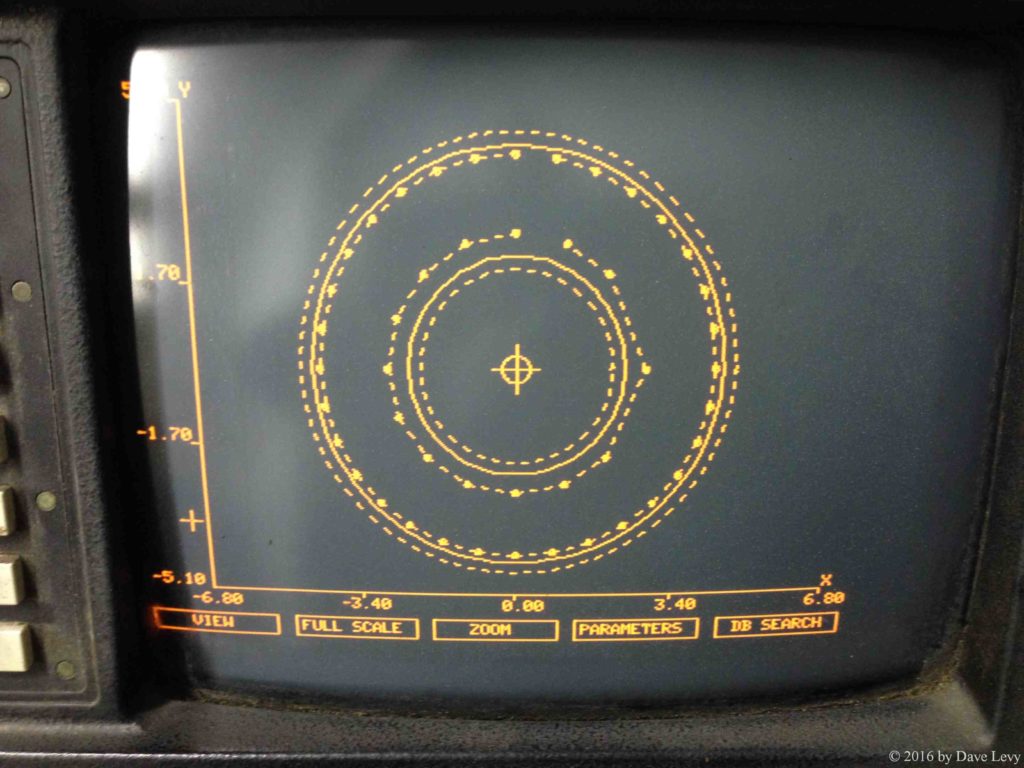

A little progress has been made since the last update. Over Thanksgiving the center truck was assembled, tuned, and painted. It is ready to go under the chassis as soon as I have some help. The plan is to have shop night at my shop this coming week so I should be able to get it installed. The third truck is well underway. The basic parts of it (side frames and lower spring plank) have been assembled and primed. The right-side journals have been installed and tuned with the line shaft. The line shaft now turns freely. Now I just need to finish fitting all the other bits (braces, upper spring plank, brake rigging, etc.) and I’ll finally have a rolling chassis. Still need to test fit the boiler to see how it sits on the furnace bearers. The Hurco CNC mill is down again. Looks to be a problem on the personality board. Am getting suggestions and help from several sources so I hope to have it working soon. I need it to machine the rear truck’s yoke.Enough typing…back to the shop!!

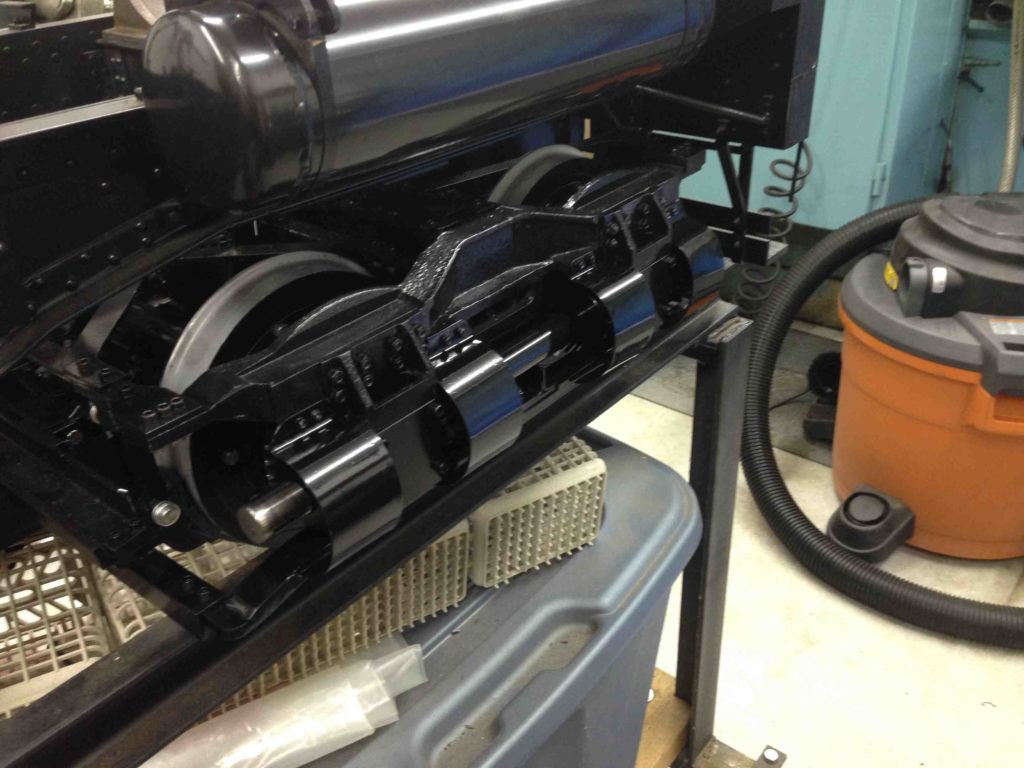

Third (Rear) Truck Completed (05/01/2015)

The third (and last) truck has been completed. Whoopee!! The Hurco is working again (memory board repaired and new batteries installed). Seems like work on the trucks has been going on forever. The year has been pretty busy with other things. In June of 2014 we bought a new 38′ 5th-wheel toy hauler RV. In December of 2014 we bought a bigger truck to tow it. The 2015 Ford F-350 dually with the 6.7L diesel makes light work of the RV. As I write this we are preparing for a month-long trip to Oregon for the 2015 Triennial meet at Train Mountain. Should be a lot of fun (how can playing with trains not be fun?).

More Progress (11/6/2015)

Looks like the travelling has subsided. The truck already has over 20,000 miles on it and it isn’t a year old yet. I’ve been able to get a few things done on WM6. I’ve had the boiler for quite some time but never actually set in in the frame. That was finally done, with some help from Wayne, to see how it would fit. It fit great!! I figured out how to mount it and then removed the boiler for further work. The boiler needs to get a coat of primer and high-temp paint. I had to trim a little over an inch off the length of the smoke box so that it would fit correctly. I know it was too long when I ordered it.

The plumbing for the propane line as well as the dual-valve arrangement has been built and installed under the tender tank. It is ready to set back on to its truck. I removed the cab floor (hopefully for the last time) to gain access to the king pin bolts. I welded a cross piece to the head so they can’t turn when installing the nut on the bottom end. While the cab floor was off, I noticed that one of the water pipes had broken at a joint. I suspect it happened while plumbing for the injectors. I’m glad I found it now. It would have been a lot more trouble to fix after everything was installed and painted. At any rate, I got the king pins welded and the pipe repaired. I’m working on the burner manifold since it is much easier to do this while the boiler is removed.

The chassis rolls really nice and easy. Need to get the draw heads machined so it can be towed to test it.

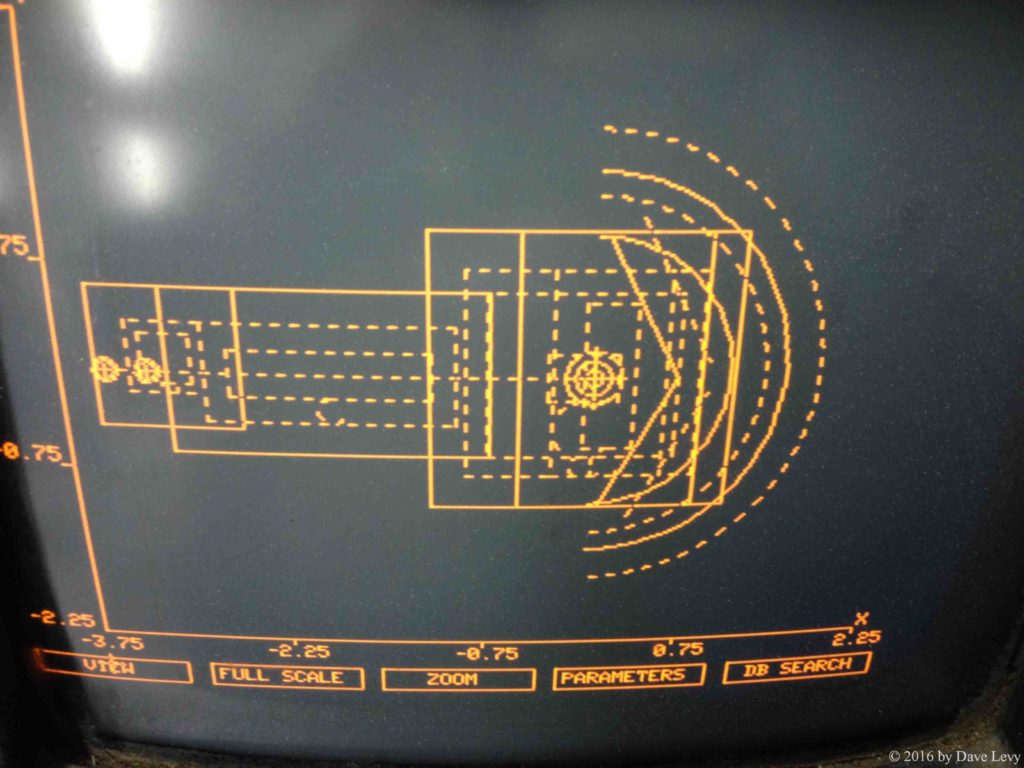

Draw heads (11/18/2015)

The draw heads have been machined. It wasn’t too bad to do. Having the Hurco helped a lot! I will get them installed soon and then make plans to get the chassis to the club track to see how it works when towing it.

Burner (12/05/2015)

I have the burner manifold put together. It should work nicely. A total of 18 nozzles that produce 5,000 BTU each. Hopefully that will be enough.

Smoke box Cover (02/02/2016)

I finally got the plate steel I wanted to make the smoke box cover. I coded a program in the Hurco to cut it out and drill all the holes. I decided to use a casting for the center door rather than make something from scratch. The interior of the door won’t be truly prototypical but it will work just fine.

Rolling Chassis Test (04/23/2016)

Managed to get it loaded into my trailer and took it to the club track for one of the club run days. I had a lot of compliments and questions while it sat in the steaming bay area on display. Then I had Wayne tow me around to see how the chassis would perform. It worked really well. We only had one derailment. The lead truck jumped off the track near the Nicol Bridge. I think that was just because there was so little weight on the lead truck. I was sitting on the tender and had my feet on the pegs over the middle truck but, without a boiler, the lead truck has almost no weight on it. In any case, it doesn’t worry me.

To watch it run, click here.