Dateline: 1999-2001

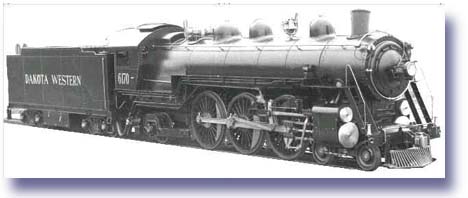

Little Engines 4-6-2 Pacific

This has been quite a project. This engine was originally put together by a high school shop class as a class project many years ago. The shop teacher ended up with the loco and it sat for many more years until he sold it to Wayne Lass. It then sat a couple of years in Wayne’s basement awaiting the “starting gun”. In the fall of 1998, I got interested in steam engines at coincidentally, nearly the same time that Wayne started working on the Pacific. We have been working on it at least once a week ever since.

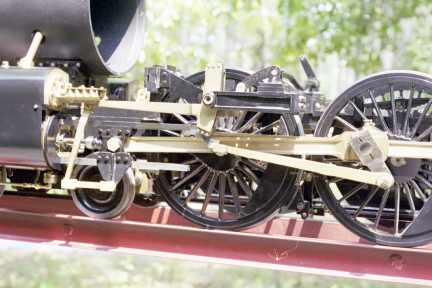

The first thing we had to do was strip it to the frame to adjust the gauge. The drivers were slightly too wide. With this fixed, we began the painstaking process of painting, measuring, repairing, and reassembling. It was soon discovered that although the engine ran on 100psi of compressed air (with a little push start), it had a lot of problems. A lot of the rod lengths and valve gear was very poorly machined. And the paint job was horrible. (It was obvious that high school students had built it!).

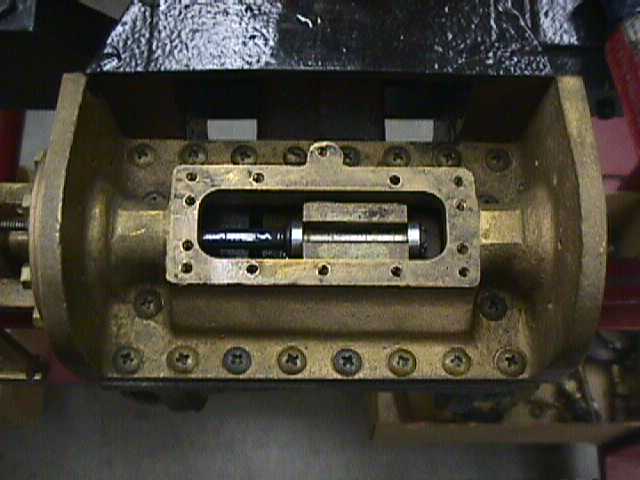

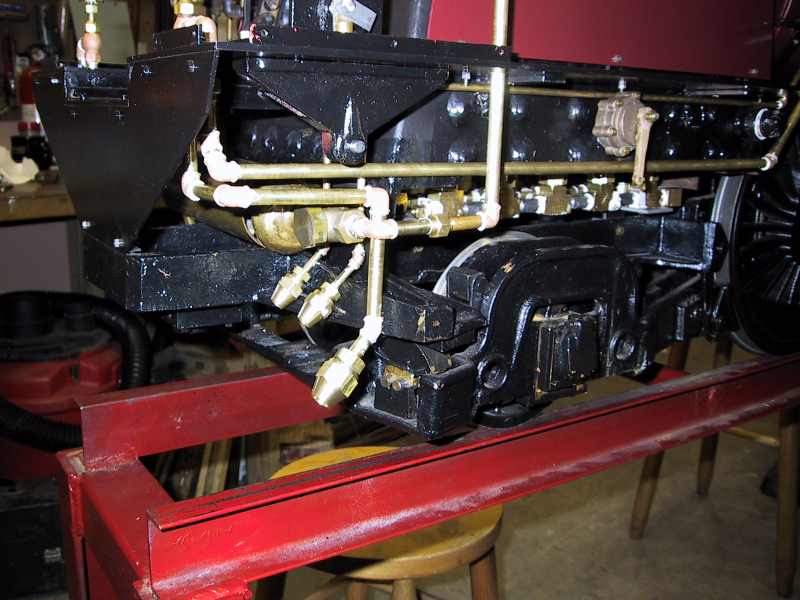

Once all the rods were fixed and the valve gear was fixed and reassembled it began to operate more smoothly. The cylinders themselves were well machined but the steam inlets and other parts had to be spruced up a little. After many months of filling holes and re-drilling and repainting and reassembling, all the running gear was ready to be tested. With 7psi of air (that’s not a misprint…SEVEN psi), the drivers started turning all by themselves…we knew we had a good thing!!!

The front end of the chassis has been overhauled. The pilot beam has been filled, drilled, and painted. A coupler release rod has been added. It looks great. The smokebox has been sand-blasted and painted and mounted. Another fine looking item. The smokebox door is soon to be completed. It needs the headlight mounted and a coat of paint.

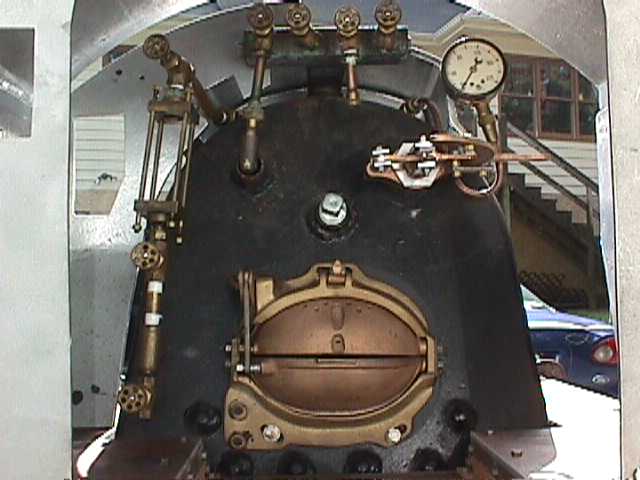

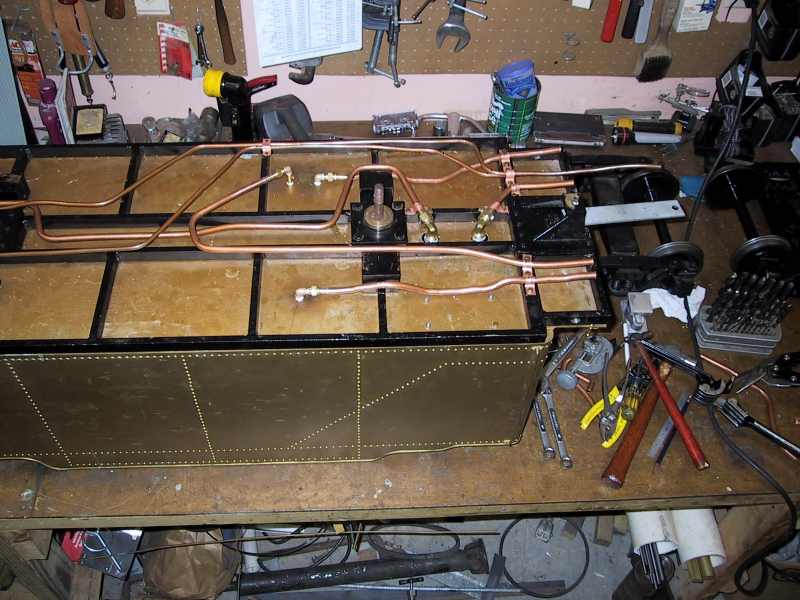

The boiler is still not permanently attached to the chassis. We are currently working on the plumbing (water, steam, and lubricator). The cab floor has to be fashioned yet also. The boiler itself is ready for the jacket mounting rings and then the jacket and its paint. The back head needs the water glass relocated and a fire door attached. Still lots to do!!

Here are some pictures of the various stages of rebuild. Enjoy!

New pictures (8/7/2000)

Status Update from the CEO of Fairfield RR (08/13/2000)

Time for a new update. I have completed the lubricator and plumbing. I have rebuilt the fire door and installed it. Looks good. Works good. I have completed the throttle and installed it. Looks good. Works good. Have reassembled the cab for fit-up. Looks large. Need to replace bolts with flat head screws to hide them, then fill holes and repair rivet detail before it’s ready to paint. The whistle works! Loud!! Next I will start on the running boards and brackets. That should slow me down a little.

Status Update and Work Plan from the CEO of Fairfield RR (08/26/2000)

Hi: All the old brackets have been removed from the boiler, the new ones have been added, and it has been painted except for the back head which gets another type of paint. The water glass is ground down. The cab floor is finished. As soon as we finish up a couple of pieces of plumbing in the chassis, and make a rotation adjustment to the smoke box, we are ready to set the boiler on the chassis. Then we can make adjustments to the cab floor and make the last brace and mount. I have the stock for the jacket and know what has to be cut. Once it is formed, we can fit it to the boiler, fit the cab to the jacket and add the running boards and domes and it is ready for paint. Then we can clean up the tender and take it all over to the body shop for paint. While it is being painted we can build the water pump and the propane burner, and mount the brakes on the trucks. Then we can assemble and plumb the frame ready for the stuff to come back from the paint shop. Then we reassemble everything, finish the plumbing, add the decals and steam it up! It is getting close!

Status Update and Work Plan (11/30/2000)

Well a good bit of progress has been made over the last few weeks. The cab floor is completed and all holes/slots in it are machined. The first (rear-most) jacket section has been mounted and brackets made to fasten it to the cab floor. The backhead plumbing is complete less a few minor adjustments. The water glass plumbing was a nightmare and took much longer than anticipated to get it steam tight. The brake stand has been plumbed with its pair of pressure gauges (it looks fantastic!). The Johnson bar is mounted and the reach rod is being built now. The front-most sections of the cab have been machined to properly match the contours of the boiler jacket. The plumbing for the injector has also been completed. The tender was just recently fitted with its newly completed hand pump and the interior plumbing has been done. In-progress items include the reach rod, mounting the whistle, repairing the tender hand rails and getting it to the painter for a new paint job. The “to do” items include fitting the remainder of the boiler jacket sections, laying out the hand-rail holes and other mounting holes in the jacket sections and getting them to the painter, completing the plumbing that lies in the tender frame (water feed, return, LP gas, and compressed air (brakes)), fitting brakes on the tender, completing the cab and getting it painted, designing and machines a drawbar, and about a thousand other things!!

Boiler Gets Jacket…Finish Line in Sight (12/22/2000)

The Fairfield Railroad Pacific locomotive is taking shape. Today the boiler jacket was assembled on the boiler, the cab floor was mounted, a blow-down valve installed, running board construction started, the burner manifold was built, several parts were painted, cleanup work continues on the cab, and the injector plumbing was started. We are still planning for a January 1, 2001 first run, but there is still much to do. There are additional details to be added, such as hand rails and wiring for lights.

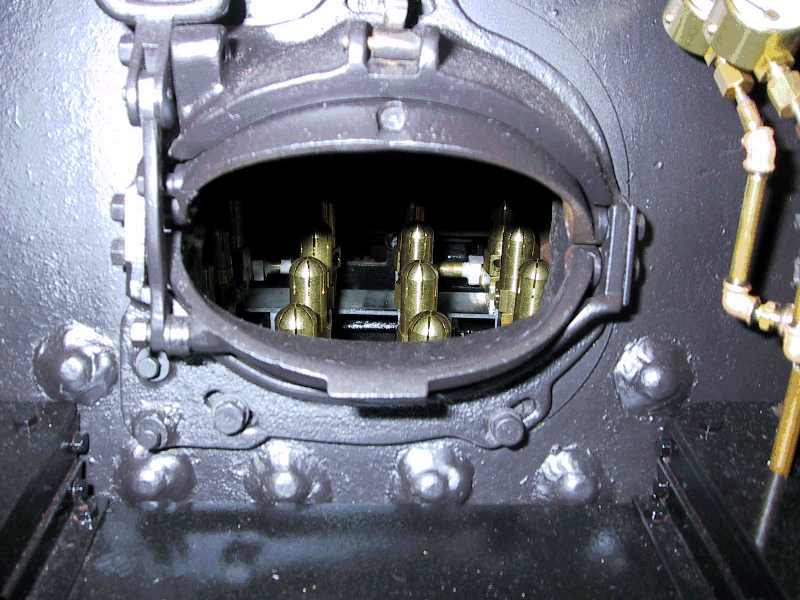

Fire in the Belly of the Beast! (12/29/2000)

At 9:30pm today, after a successful hydro test, a fire was lit in the firebox of the Fairfield Railroad Pacific Locomotive number 169 for the first time ever. The propane fire was allowed to burn a couple of minutes for visual inspection and then was extinguished. It was a complete success with the 20 Barber-style burners laying down a beautiful sheet of blue flame.

There were only a few minor leaks on the feed water plumbing which will be attacked tomorrow. The leaks are so minor that I would feel completely comfortable running the engine. Weather is threatening the New Years Day run, but the engine is almost ready except for tender paint and the above mentioned leaks, so the goal of being ready to run for January 1 has been reached.

New Years Day Maiden Run of Pacific! (1/1/2000)

At approximately 11am today, the Pacific was unloaded, prepped, and fired for its maiden run. Everyone waited anxiously for the steam pressure to rise and all preparations to be made. Approximately 30 minutes later all was ready and owner Wayne Lass eased the Pacific, whose name is Lady Barbara, out of the yard onto the mainline. It was a momentous occasion culminating over two years of work (and a last of week of 12 hour work sessions). With only a couple of very minor leaks that did not interfere with the days running, the Pacific performed flawlessly the entire day ending at around 4 PM. See the pictures below and also refer to the New Year’s Day 2001 Run page for further pictures and movies!

Second Run of Lady Barbara is a Success! (03/23/2001

Lady Barbara and the little American loco both passed hydro testing and state boiler inspections today. While there was never any doubt for Lady Barbara, there were a few tense moments for the American when a check-valve would not seat properly. With a little ingenuity, the problem was resolved and the boiler was passed.

Later in the day and back at the Fairfield Railroad yard, Lady Barbara was unloaded and coupled to her tender and support car. The fire was lit and steam was made. Once again Lady Barbara performed beyond expectations as minor adjustments were made. After 3 hours of marvelous running, the fire was dropped and she began to cool down. During this time (and starting with 110 pounds of pressure), 5 more rounds were made around 700ft circle before the run day was concluded with 30 pounds of pressure remaining.

To see a short video clip of the run day, click here.