2020-????

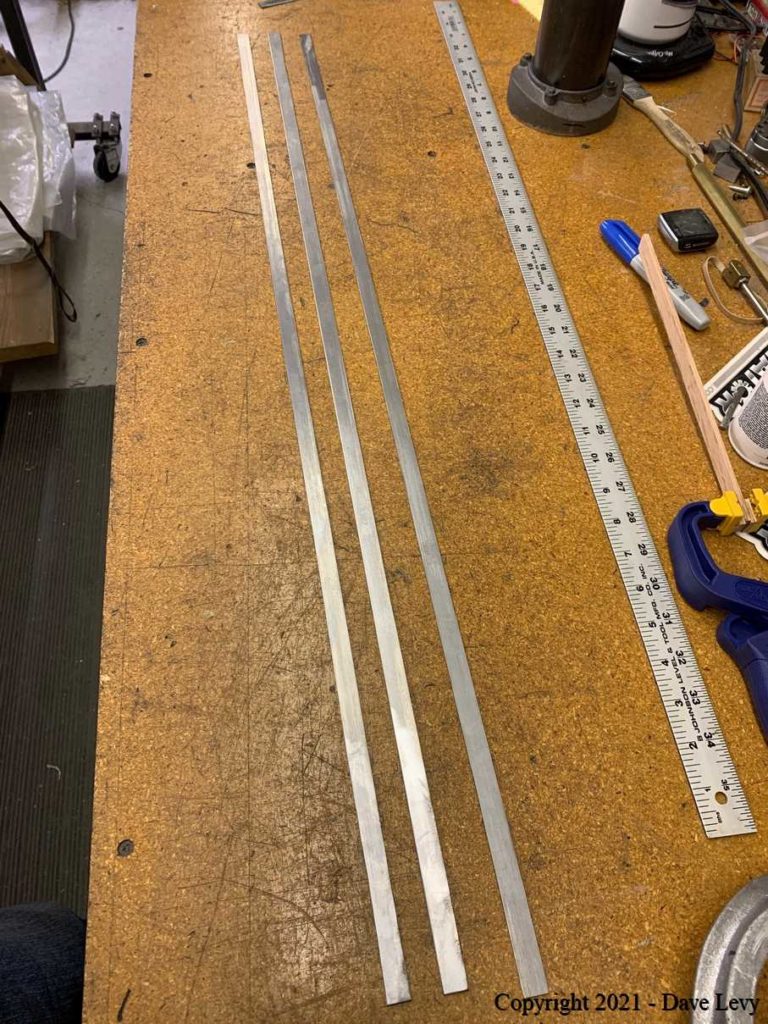

Line Shaft Slip Joints (01/06/2020)

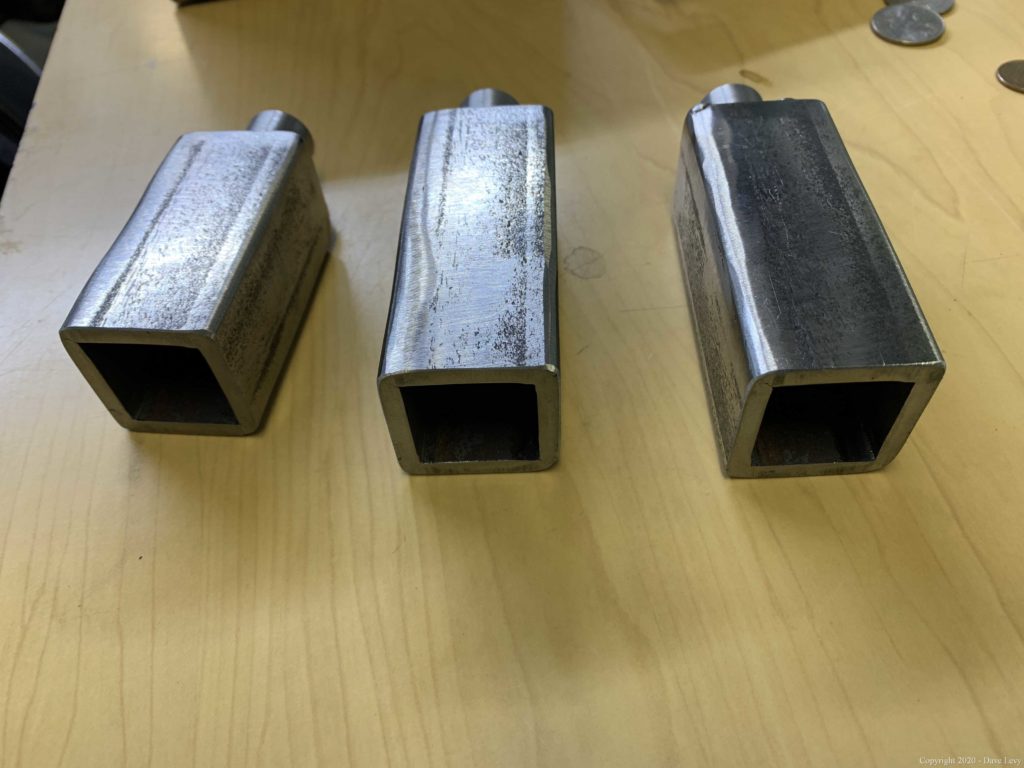

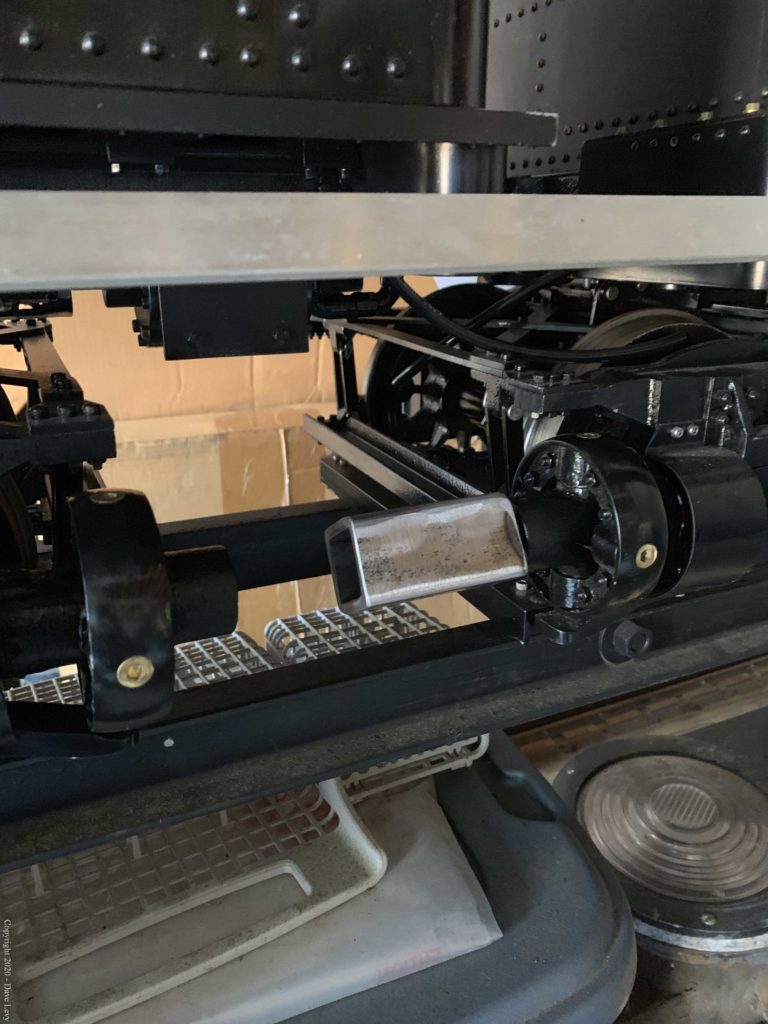

Well…it has been a while since I worked on WM6. Too many other things kept getting in the way. I’ve recently, however, fabricated the line shaft slip joints that connect the trucks together. I can only install the one between the tender truck and the middle truck since I don’t have the motor built yet. The outer slip shaft is 2 pieces of angle iron welded to form a hollow square. The inner shaft is 1″ square bar stock machined to have a round end to go into the universal joint. A similar round stub is welded into the end of the hollow tube so it will fit into the other universal joint.

Here are a few pictures.

Eccentric Straps (03/06/2020)

It has been a long time coming but I finally got around to machining the eccentric straps for the motor. I cut out the blanks in 2007 and machined the inside races in 2009 but they have been on a shelf waiting for the final machine work ever since. No one will accuse me of rushing into this. Here are some pictures of the final eccentric strap and eccentric cam that will be pressed onto the crankshaft when it is fabricated.

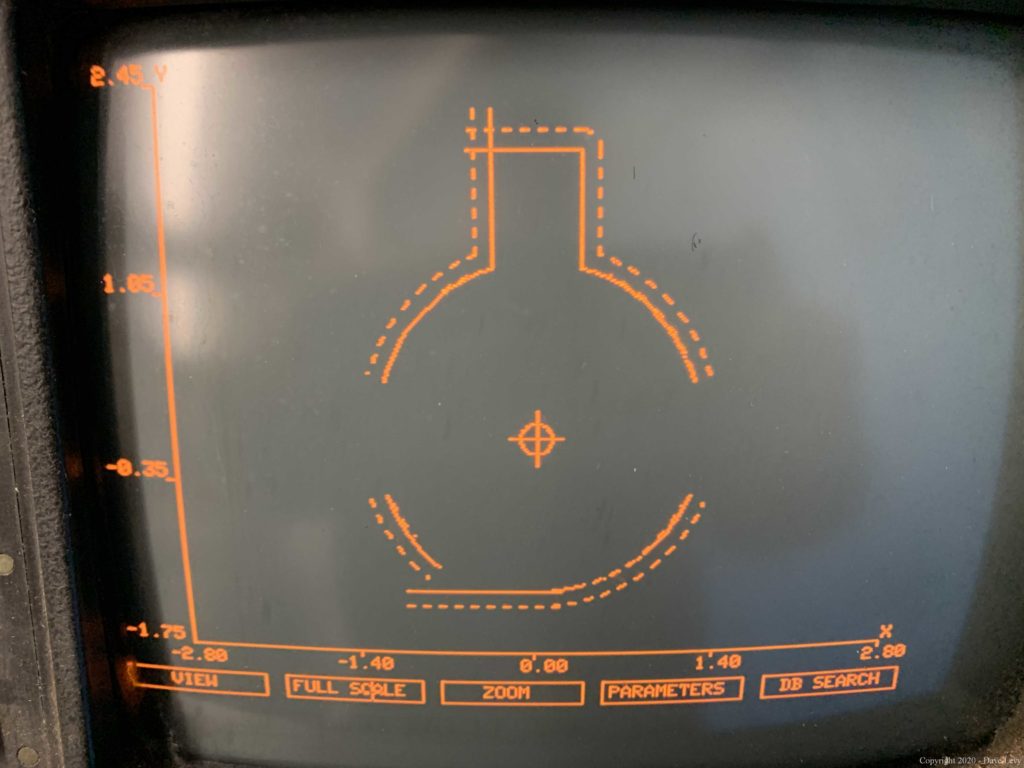

Left side rendering by Hurco mill

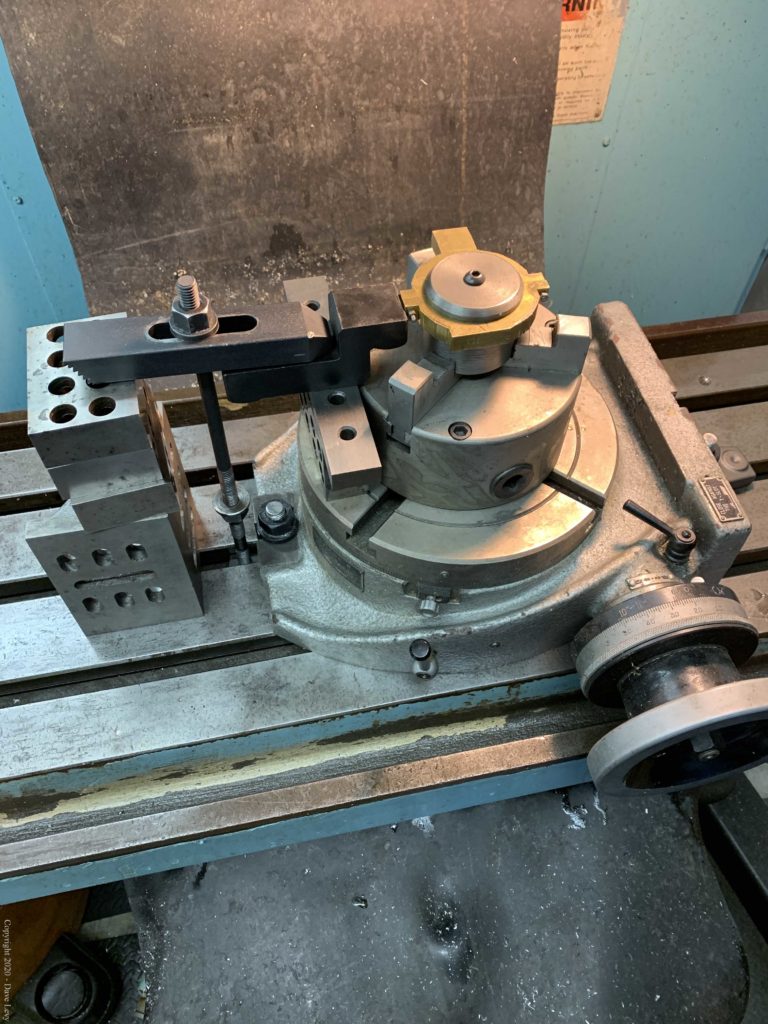

The setup

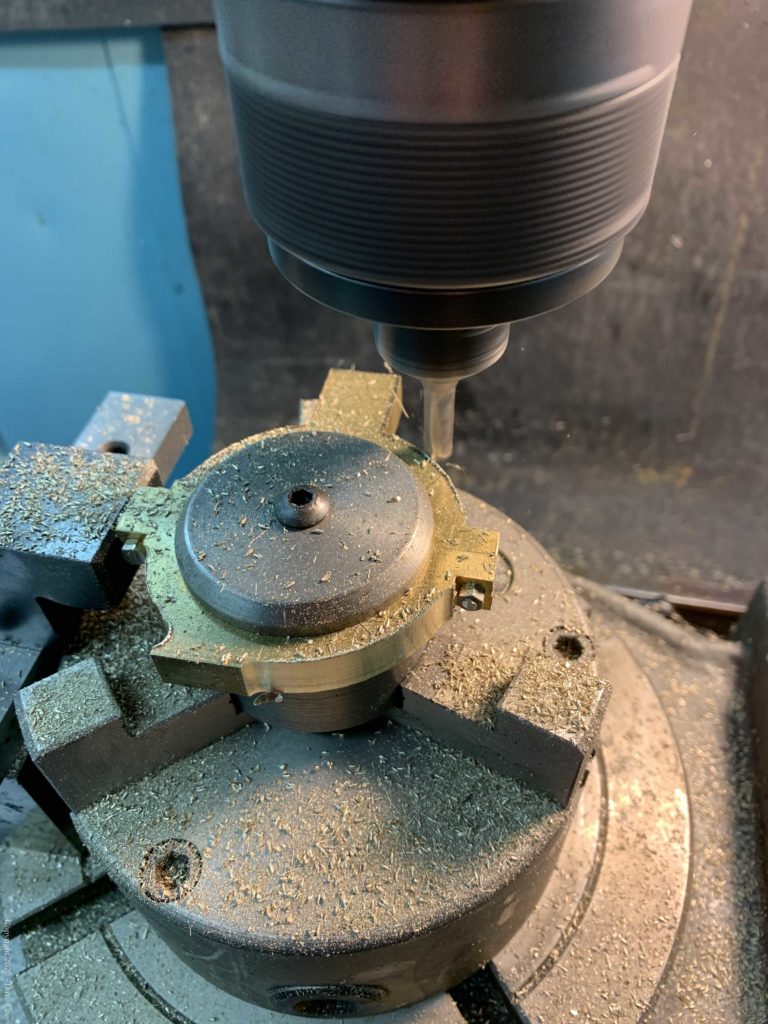

Macining in progress

The final product

Test machining of cam

Finished with eccentric cams

Motor Base (April-May 2020)

The machining of the motor base casting has started. There is quite a bit to do on it but it all seems to be manageable segments. I ended up needing an extra long 1″ diameter roughing end mill to be able to reach down into the lowest parts of the internal cavities. The goods news is that the machining is all done. Next up is the fabrication of the crank bearings and their holders.

Checking casting dimensions

The machining begins

Top is flat

Bottom is flat

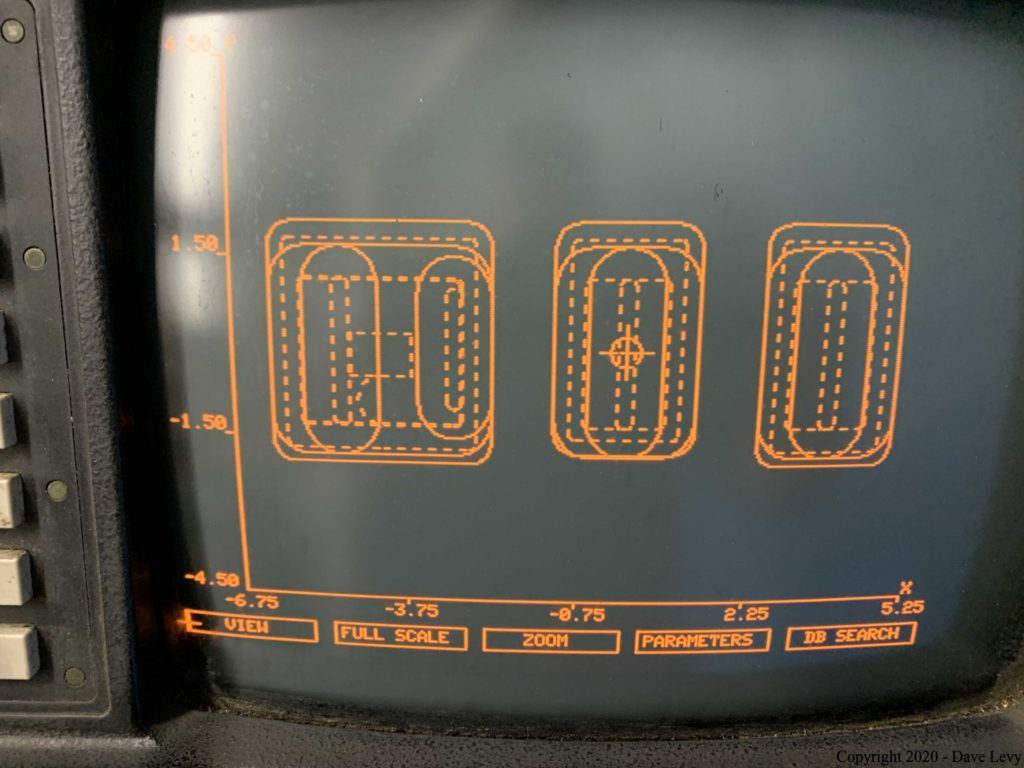

Machine tool paths

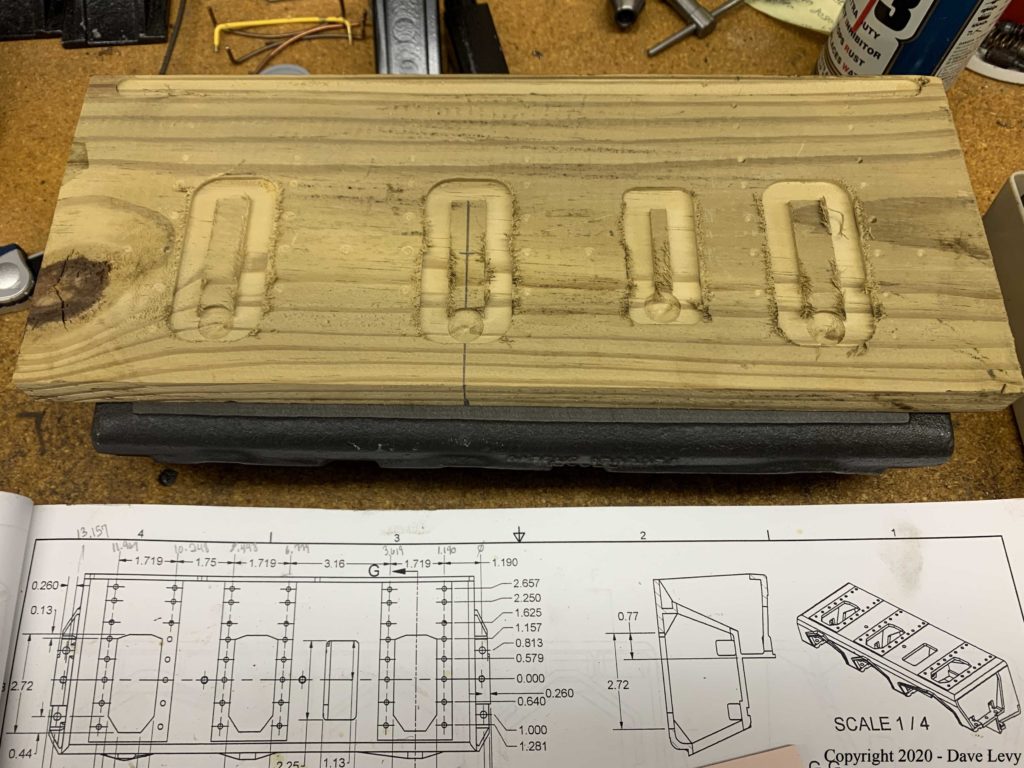

Test of machining program

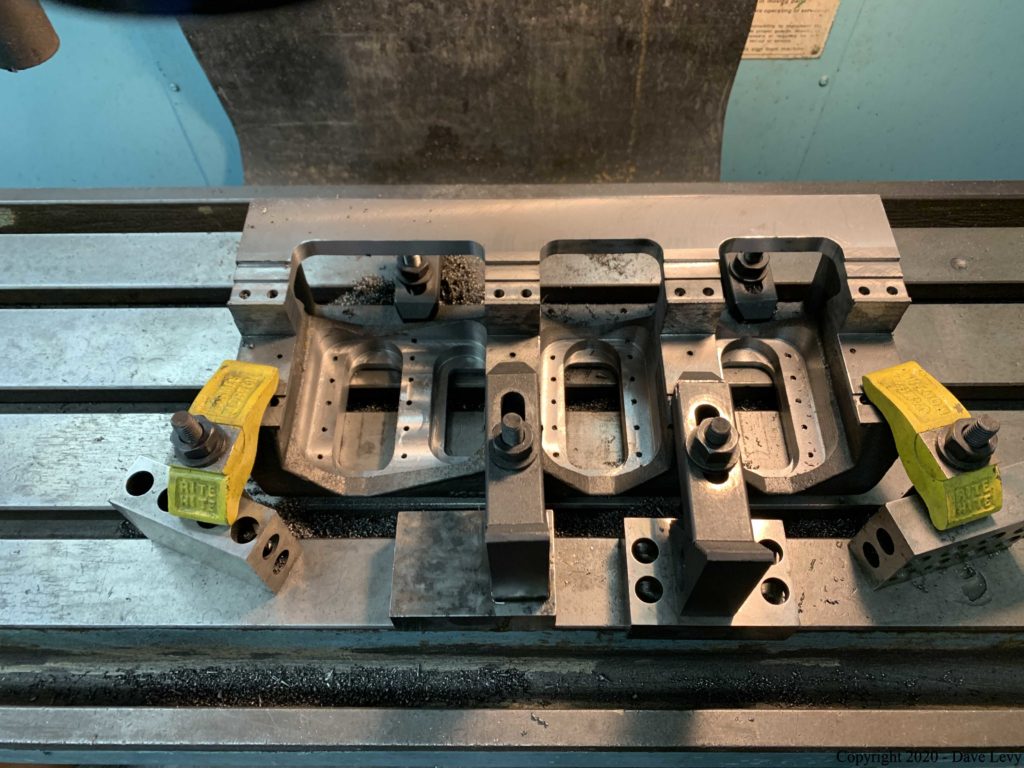

Holes drilled…ready for cutouts

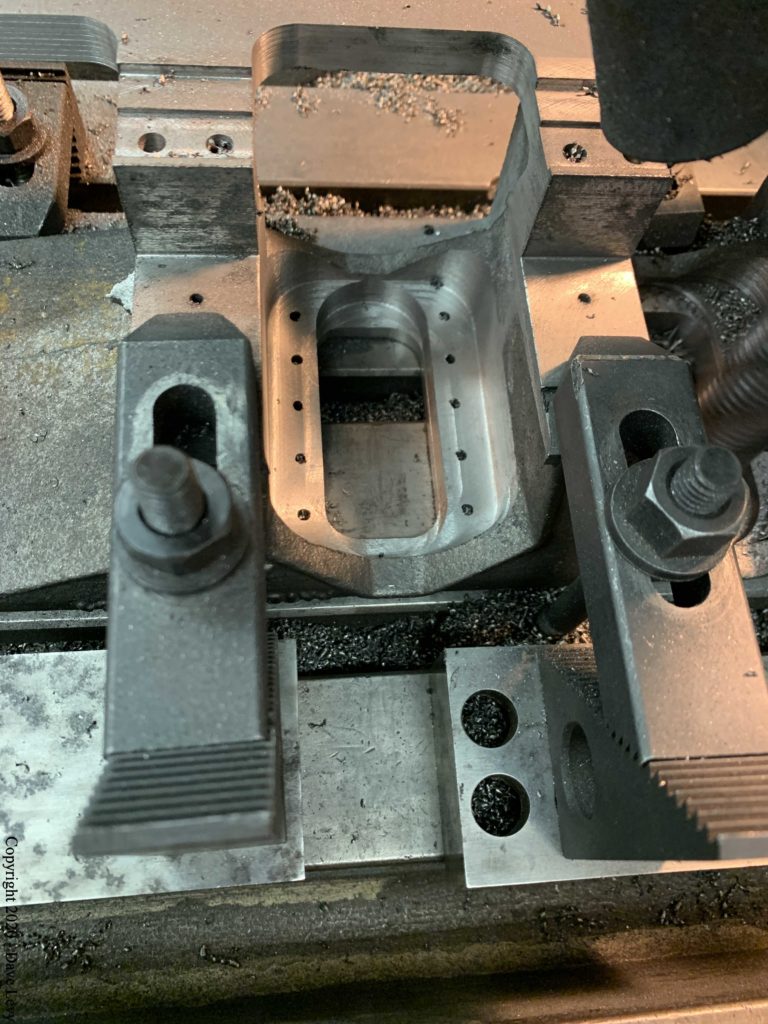

Cavities machined. They will “fall out” when underside is machined.

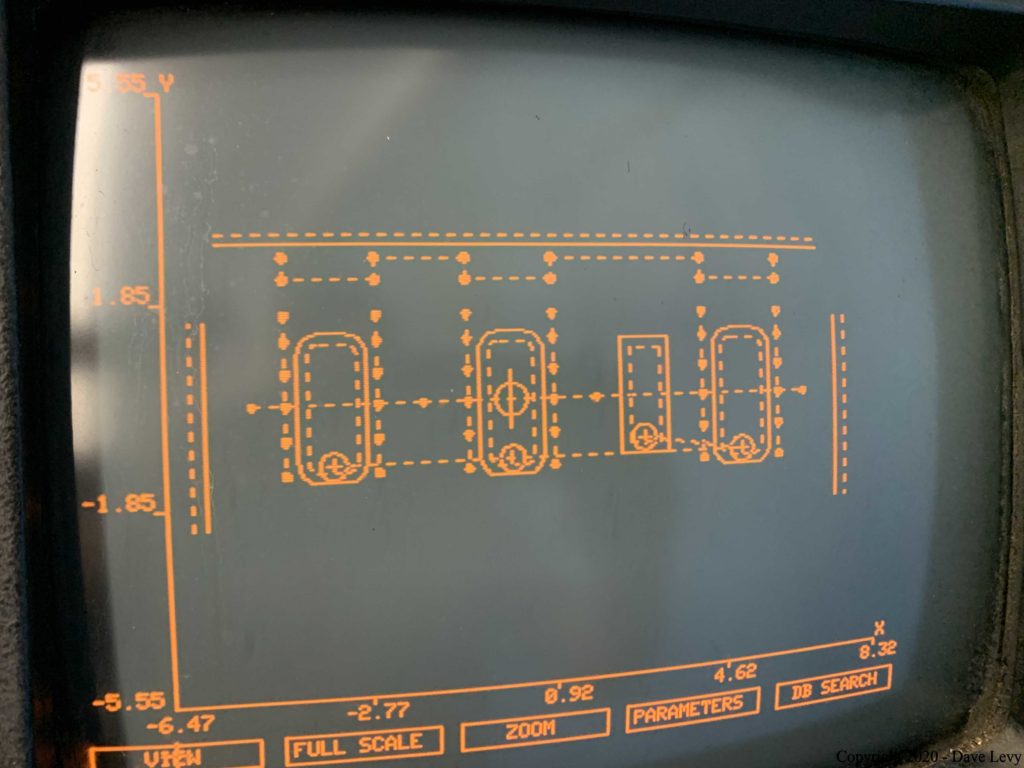

Holes and slots for crank bearing holders

First bay completed

Carving the second bay

Internal carving program tool paths

Internal cavities completed

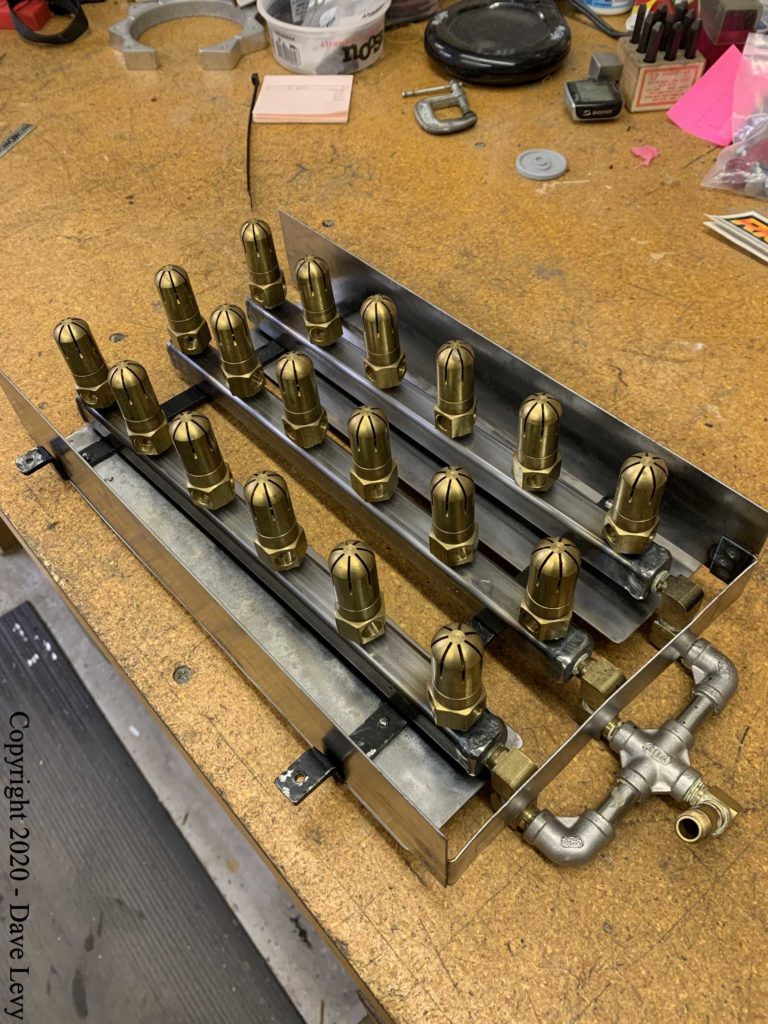

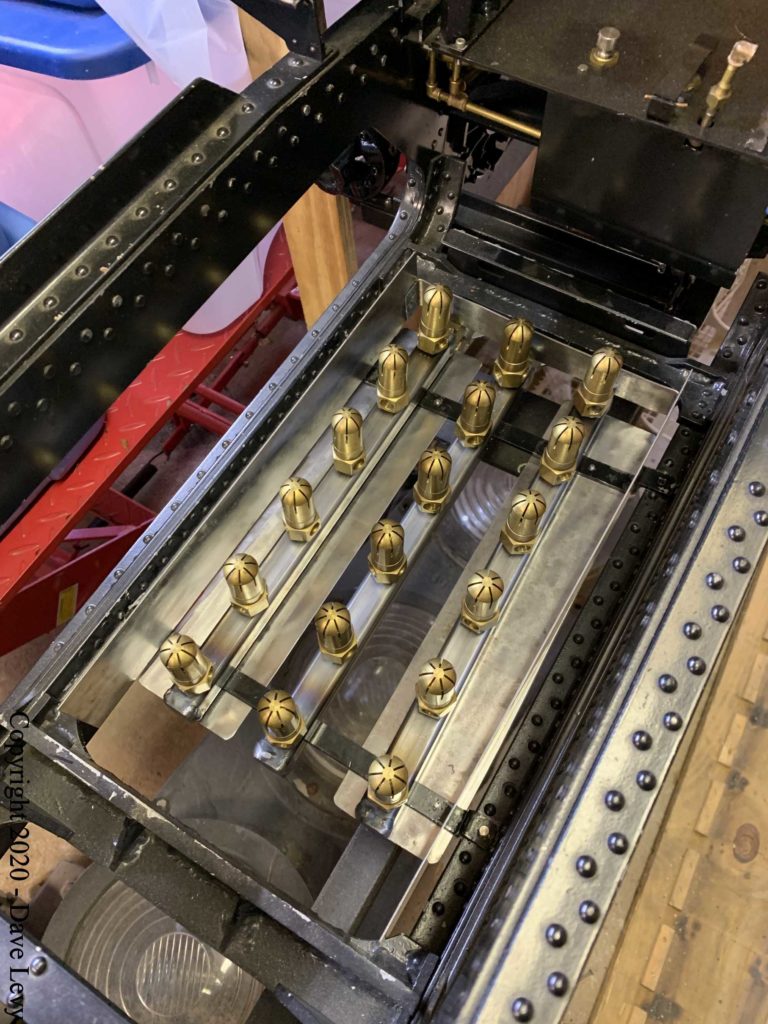

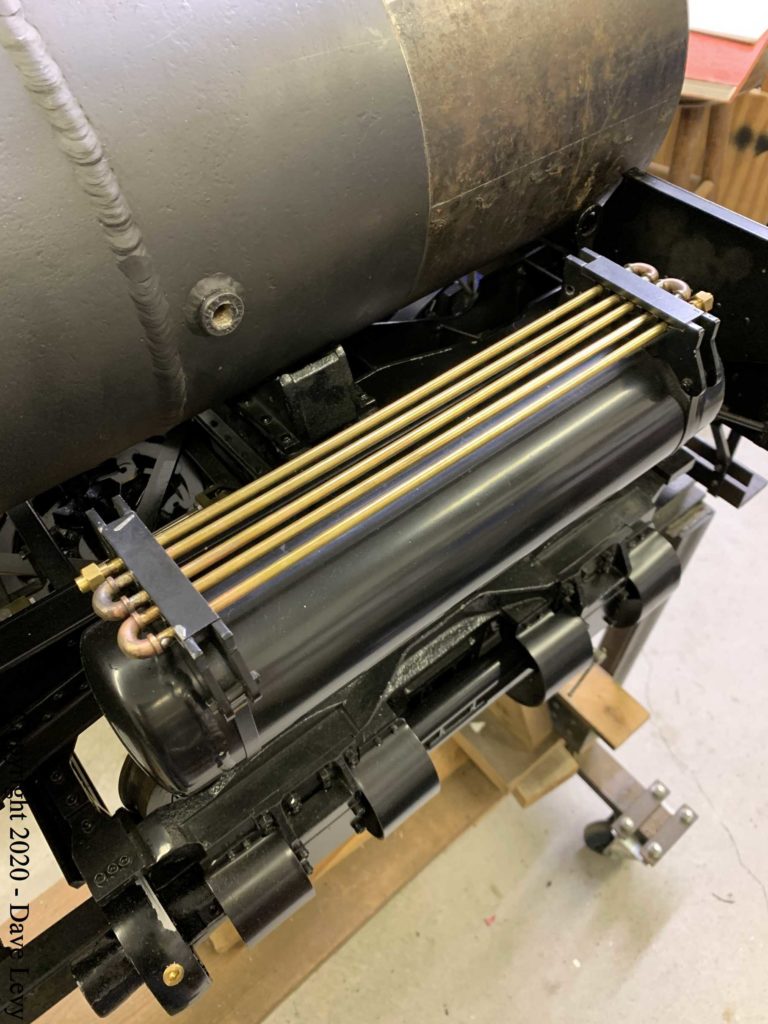

Burner Assembly (12/06/2020)

The burner assembly is completed. It has 18 burners, side draft protection, and an air flow control panel on the bottom. The arch is also complete and mounted in the frame. The boiler can now be mounted (for the last time).

Miscellaneous (12/23/2020)

Now that I have the boiler mounted on the frame, I’ve started working on miscellaneous items while I wait for repair parts for the CNC mill.

Smokestack

The smokestack assembly is completed. The base still needs to be fly-cut to an arc that matches the smokebox diameter. That will have to wait until the CNC mill is fixed. I also added a rivet detail to the smokebox.

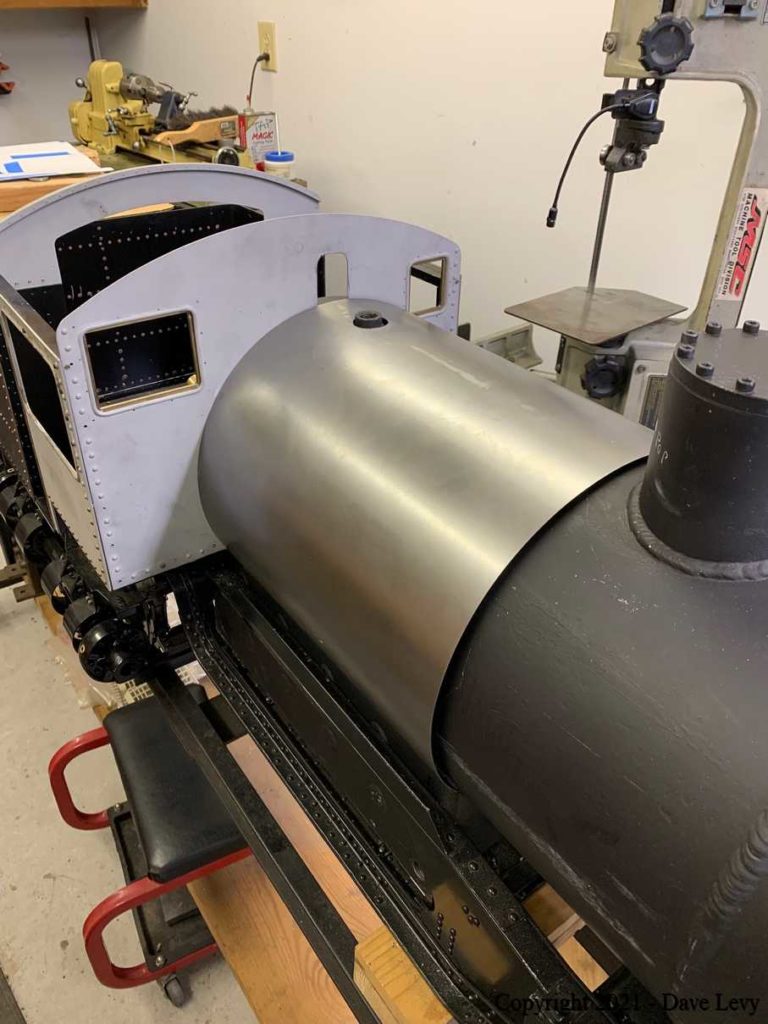

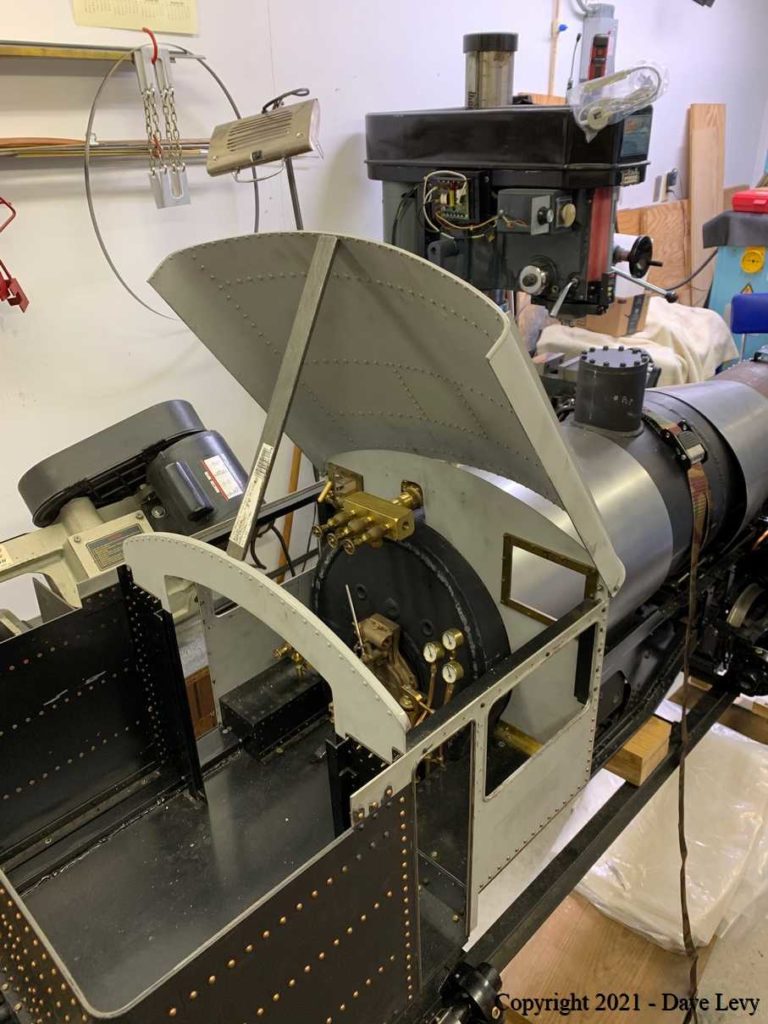

Boiler jacket, bands, and roof

Making progress on the boiler jacket. Also got the roof hinges installed. Once I get the jacket installed (without paint), then I can attach the generator, bell, and fit the domes. One step at a time.