Dateline: Jan 2008 – Feb 2010

Little Engines 4-6-2 Pacific for Tom Hill

Tom Hill of Florida has had this locomotive for many years but due to employment obligations and several relocations the locomotive has had trouble getting reassembled after it was taken apart for repairs and rebuilding. After a little horse-trading, the locomotive was transported to the Fairfield shop for the Monday night rebuild team (Wayne and me) to tackle.

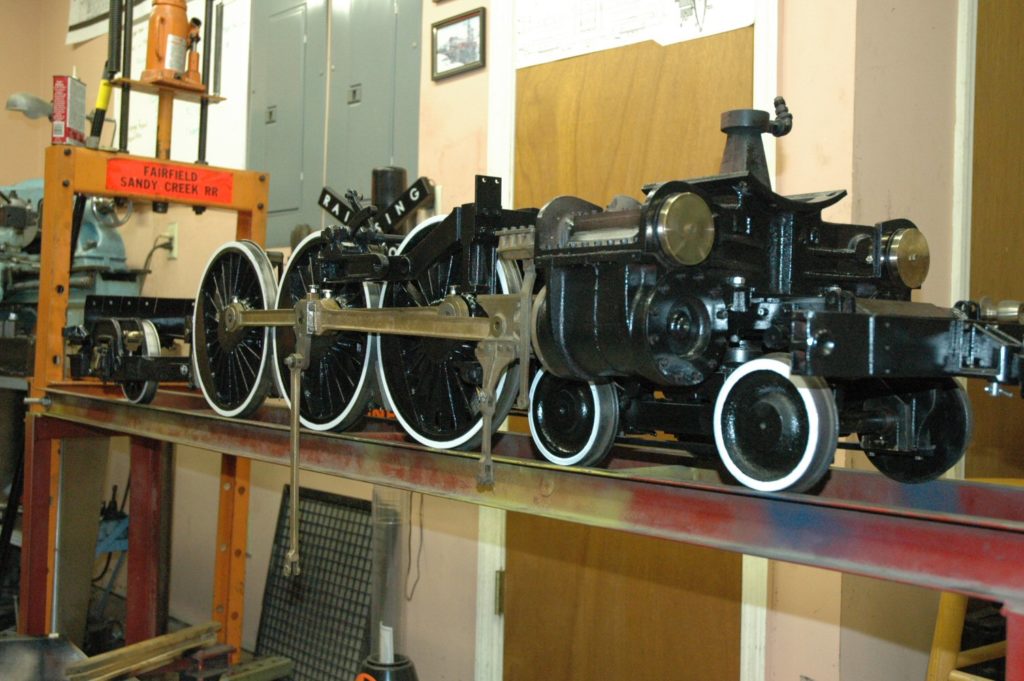

Frame (1/15/2008)

The locomotive was completely disassembled to the frame so everything could be checked and rebuilt as needed. The frame was then painted and the drivers re-attached to make a rolling chassis again.

Boiler Mount (3/10/2008)

The boiler gets mounted again. It makes the whole thing look a lot bigger!!

Smoke Box (7/14/2008)

The smoke box gets some cosmetic touches including rivets, door hold-downs, and a headlight. The devil is always in the details but it is what makes a loco look good!

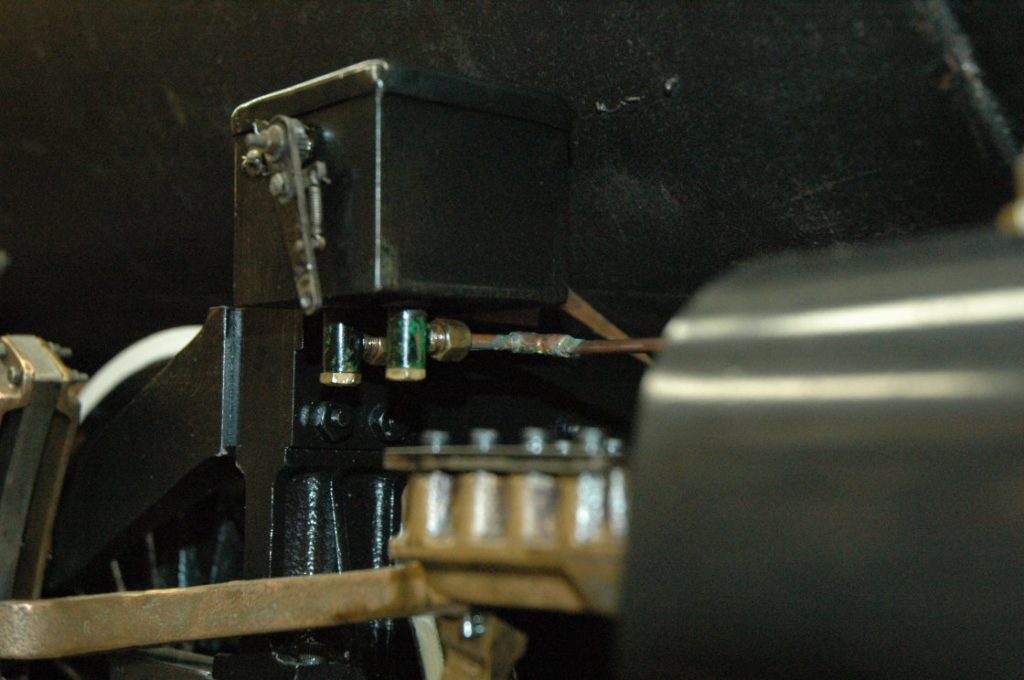

Throttle, Lubricator, and Cylinder Feed Collars (7/14/2008)

Here are some shots of some of the devices that make the loco work as well as look good. You never see the throttle but you can not run a loco without one!

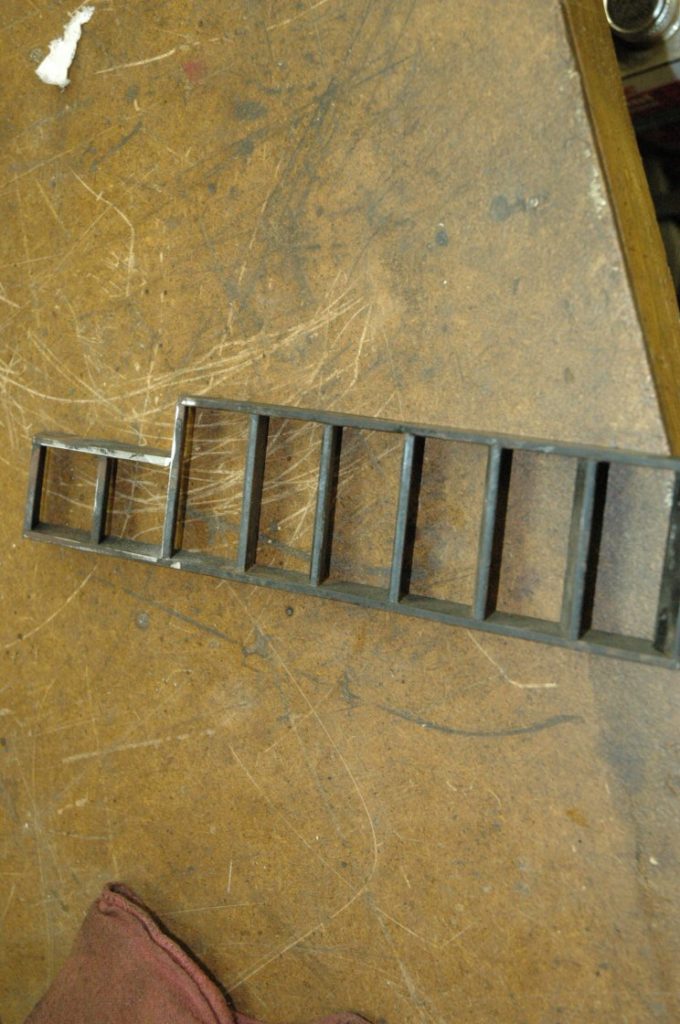

Ladders (9/1/2008)

The original locomotive ladders were salvaged but were never mounted so they were square to the running boards. To get them to mount right, they needed some modification to narrow up the top two rungs of the ladder. Here we see Dave doing the needed modifications. Now they will look right when mounted to the front buffer beam.

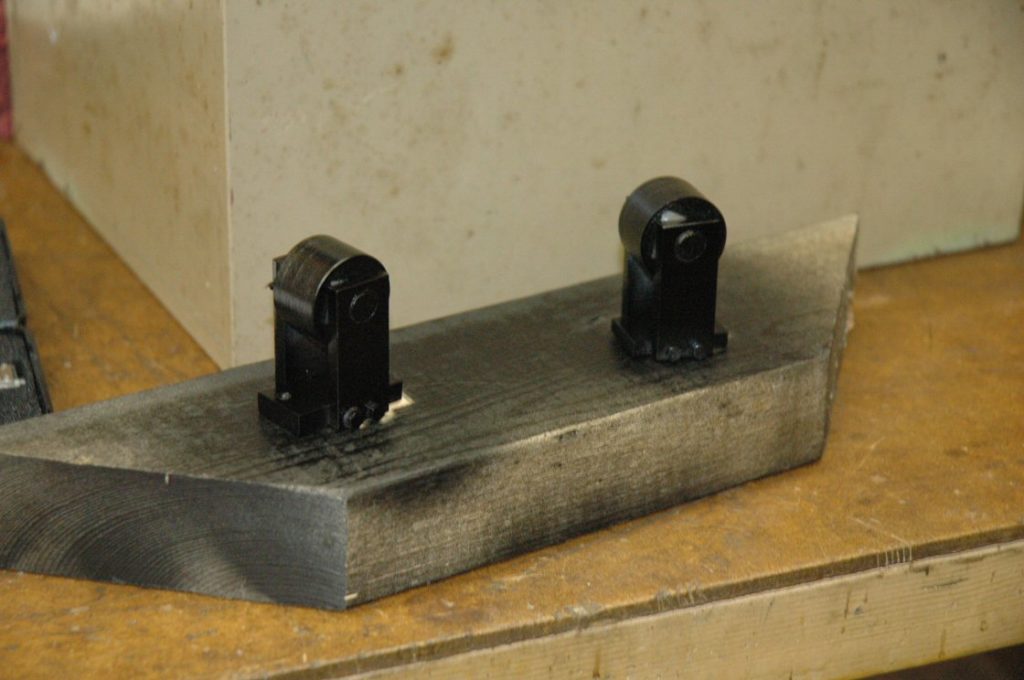

Trailing Truck Rollers (9/1/2008)

The original trailing truck uses heart-rockers to allow the trailing truck to move side-to-side and at the same time change the height and pitch of the truck. This is very effective in the prototype but somewhat less so in the scale model. In short, they are problematic and tend to fall over and become useless. As a result, we have replaced the heart-rockers with simple rollers that cannot fall over or become a problem. This has worked successfully on other locomotives so we are confident it will work well on this one.

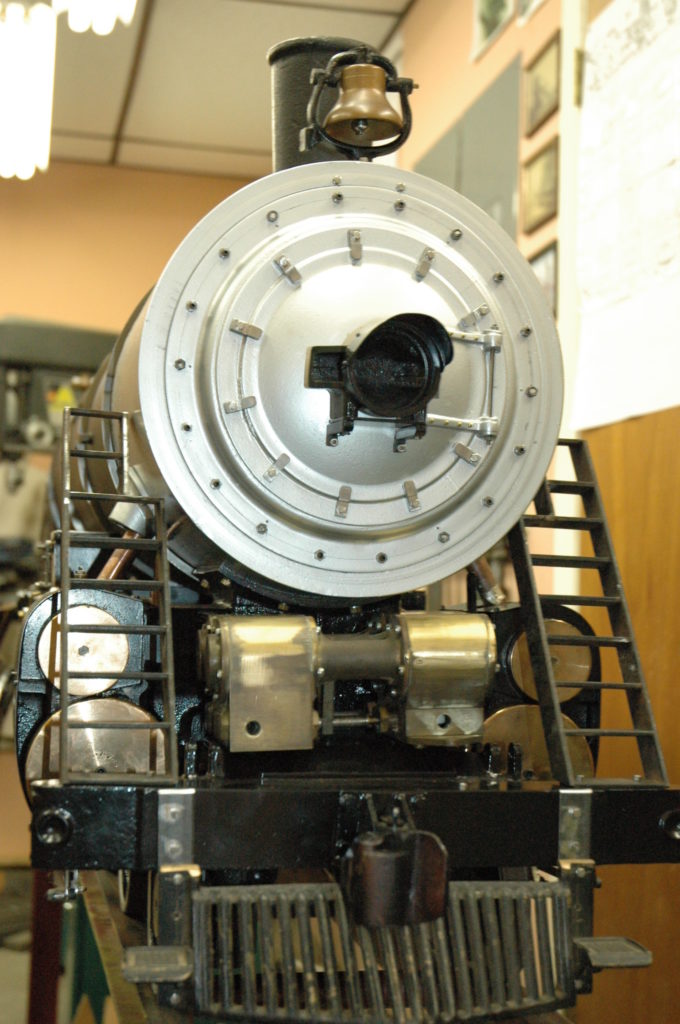

Front View (9/2/2008)

Here are a couple of shots of the front end after assembly. Notice the smoke box door detail and the ladders mounted to the running boards. We think it looks pretty good and hope that you agree. BTW: Pay no attention to the water pump lying under the smoke box!! It was just lying there for storage…this is NOT where it will be mounted.

Backhead (9/2/2008)

Here we see some of the attachments that mount on the backhead. The backhead has been painted and the throttle and water gauge glass mounted. Note the inspection plug in middle of the backhead is removed and you can see in to boiler to the top of the crown sheet. Although it looks a bit rusty, the boiler is in very good condition, especially considering its age.

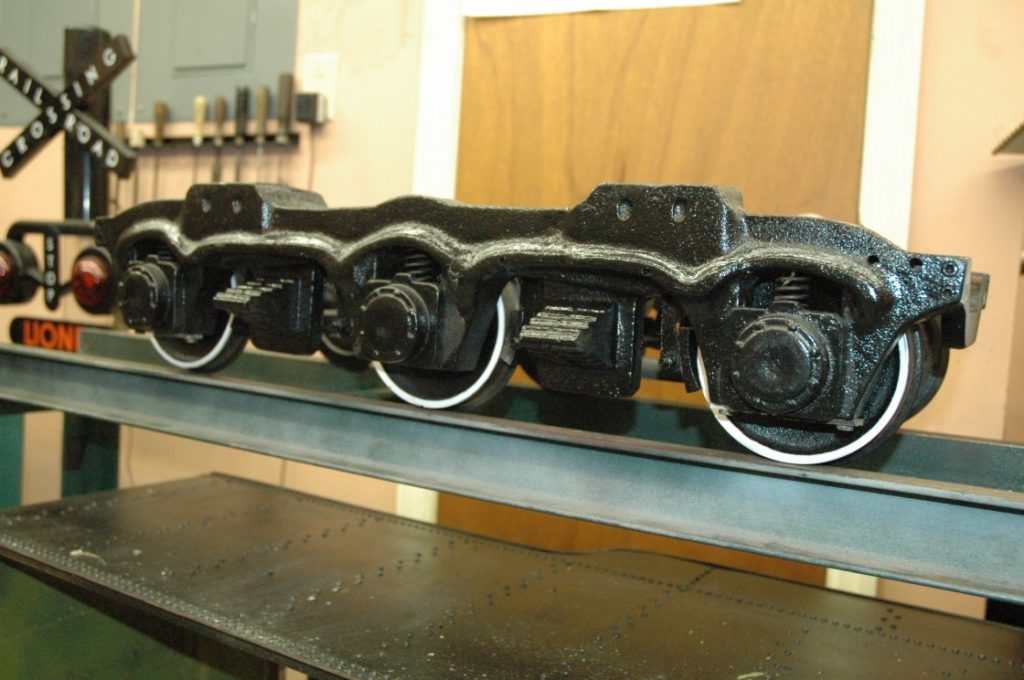

Tender Trucks (9/29/2008)

We took a small break from the loco to work on the tender. While the tank itself was a bit rough looking, it was in pretty good shape. A little new plumbing under it and some paint and it was done. Below we see one of the trucks “before” we started working on them. They were in tough shape and needed some bearings replaced. After a little sand-blasting and some paint, they look as good as they roll!

Tender Gas Valves (11/24/2008)

Tom is planning to fire the loco using LP like many of us do. It is clean and easy to use and very effective as a heat source. To manage the gas, we provide a 2-valve system. One valve is opened and set to an idle-size flame. Then the other valve is opened as needed to create a fire of any size needed. This system prevents the accidental “shut off” of the fire that would require a re-light on the mainline. We have this system on several of our locomotives and really like it! You also see a picture of Wayne hooking the as-yet unpainted tender to the loco to test the placements of everything.

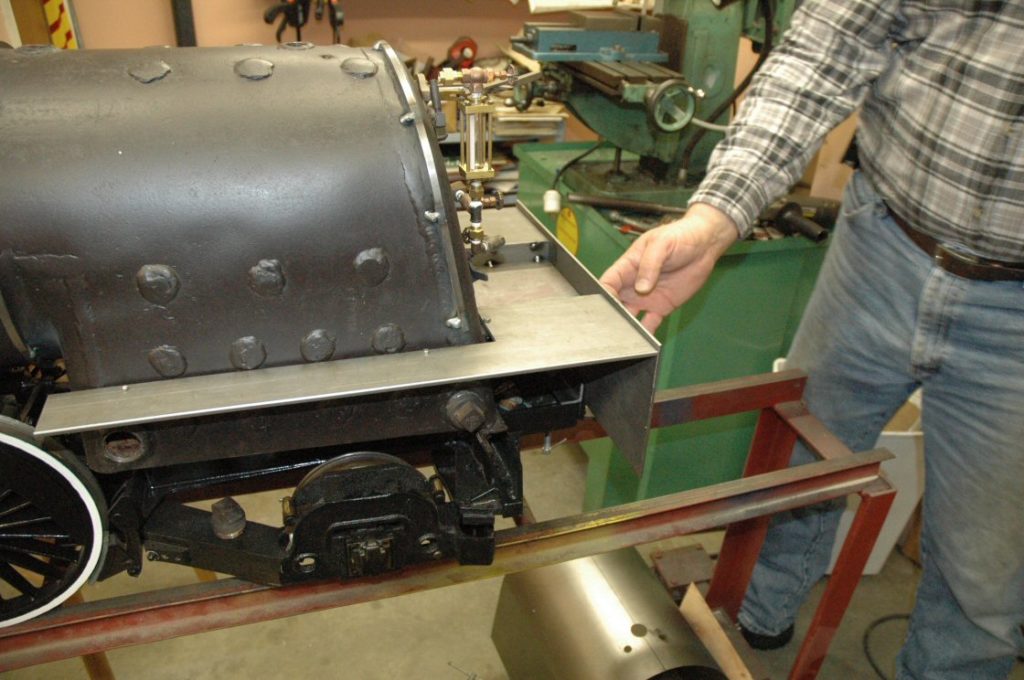

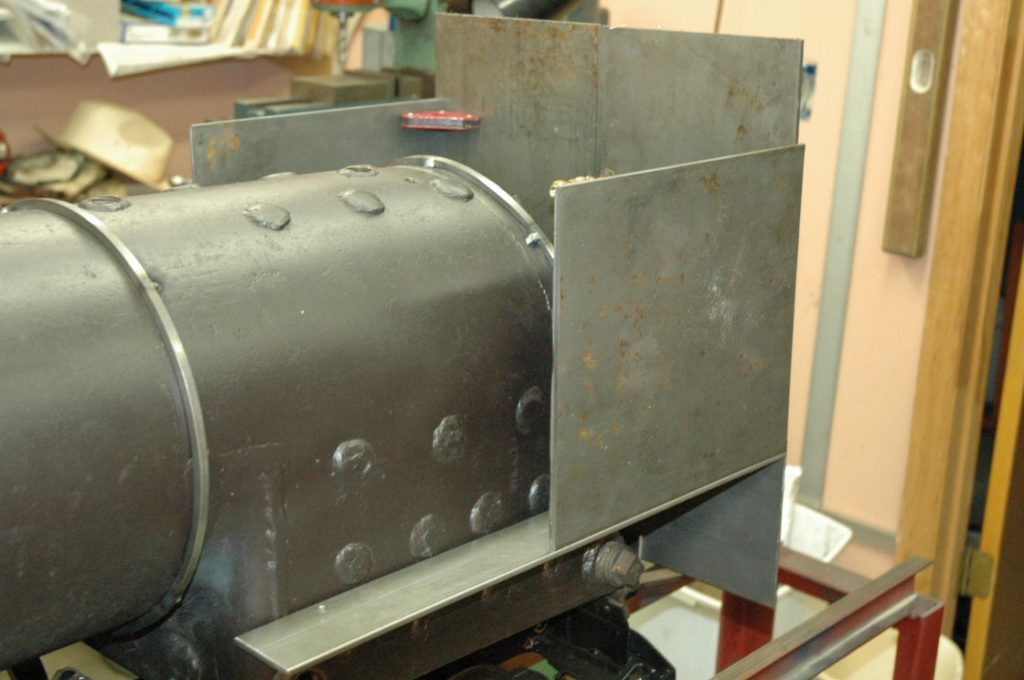

Jacket, Cab Floor, and Cab Sides (12/16/2008)

Here we see a test mounting of the new boiler jacket. Also we have just mounted the newly fabricated cab floor. The steel blanks for the cab sides have been set on the cab floor just as a sanity test that they will be big enough and of the correct height. Everything came out just as we planned so we could continue with the fabrication process.

Mockup (1/3/2009)

Here we have taken a couple of shots of a mockup we did to see everything in place. Notice that the running boards have been cut and are resting (unfastened) on the mounting brackets (which are held in place by clecos at this point). Notice also that the steam-powered water pump has been mounted. Mounting points were welded to the boiler shell to provide a solid mounting for this rather heavy pump. All looked pretty good so it was shortly thereafter taken apart to be painting and continue the work.

Run and Delivered (2/21/2010)

The engine was finished and delivered to Tom. Trials were conducted at the Fairfield Railroad prior to delivery. Everyone is very happy. It should run for many years.